Materials used in label printing

A label consists of several layers with alternating backing, adhesive and a protective coating. The backing can be made of film or paper. The paper label has a low cost and is easily disposed of without harming the environment. This label is made from several different types of paper.

Paper types for labels and stickers

Semi-gloss paper

Semi-gloss paper labels are designed for use on food, beverages, pharmaceutical and industrial products. It has a rather low price when printed with full colorful image.

Matte Paper

Informative and cheap matte paper labels are used for a wide range of products. Information is printed on the label using non-raster (text and solids) printing in one or two colors.

Textured paper

Used in the manufacture for:

- beer labels printing

- wine labels printing

- bottle label printing

- delicacy products

belongs to a class of special papers.

Glossy paper

Used in production of highly artistic self-adhesive labels. Printing on glossy paper is similar to printing on semi-glossy paper.

Heat-sensitive paper

Ideal for printing variable information such as bar codes, prices and weights on labels. Thermal-sensitive paper is divided into two types. Thermo ESO is an uncoated paper with no dirt-repellent properties. In most cases it is used in stores, where labelling is carried out right before the sale of goods, which do not need to be transported and stored. Thermo TOR – has a double-sided protective coating, the upper layer of which protects labels from mechanical damage, dirt and moisture, damaging the readability of the bar code, and the bottom layer does not allow penetration of components of the packaging material and glue. This type of labels is used in places of mass labeling of packaged food products.

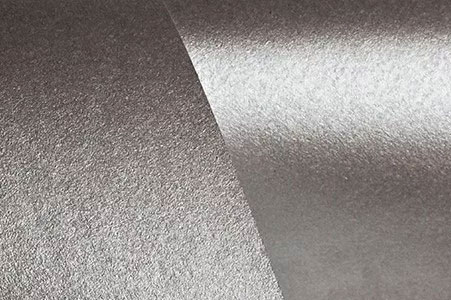

Metallized (glossy, matte and holographic) paper.

Used for production of labels for confectionery and meat products, alcoholic and soft drinks, pharmaceutical products. They have silver, gold or holographic coating.

A film label is considered more durable and resistant, which can be made of polyethylene, polyester, polyvinyl chloride, polystyrene or polypropylene. Any of these labels are resistant to chemicals, moisture, mechanical damage and temperature changes. Self-adhesive film-based labels are successfully used in environments where paper would get wet and tear. Even when such a label is used in outdoor advertising or in wet areas, it will not lose its appearance and quality for a long time. However, film labels have two big disadvantages – environmental contamination and difficulty in recycling.

Materials used in label printing

Types of adhesive component

There are two types of adhesive component that are used in self-adhesive labels.

Casein glue

Casein (water-based) adhesive is environmentally friendly, odorless, easy and harmless to work with, but there may be problems when removing it from the container due to adhesion, which may not be at its best. Also, this adhesive has a rather high cost, because it needs special conditions for storage and transportation.

Synthetic Adhesive

Synthetic (based on organic solvents) glue – economical, not subject to temperature effects, has a small consumption, but harmful to the environment due to the presence of flammable and toxic solvents.

Durability and operation of the adhesive

Adhesives are divided into three types according to their duration and operating requirements.

Removable Adhesive

Allows you to remove the label without residual traces of glue, and in some cases without even damaging its integrity, which allows you to use the label again. Used in the production of price tags, promotional labels and stickers, stickers on cars, instructions on household appliances, etc.

Permanent Adhesive

It is used in production of sticker, which is required to stay on the working surface during the whole period of its usage, and it gets damaged if you try to peel it off.

Special Adhesive

Combines a variety of adhesives in its composition, which allows it to apply the label at low temperature or room temperature with a further deep freeze, adhere to greasy or rough surfaces, etc.

Self-adhesive labels have a protective coating, either paper or polymer. For easy separation from the adhesive component, a special notch is often made on this layer.

Translated with www.DeepL.com/Translator (free version)